Ultrapure Technology’s modular cleanroom offerings include a wide range of solutions to fit your needs and budget. From seamless wall panel systems to strip curtains, there is a solution for your application. Our greatest asset to you as a client is our ability to identify the right combination of products to fit your specific time and budget. Over 20 years of building cleanrooms consisting of more than 500 projects nationwide and beyond, the construction team of Ultrapure Technology can handle it.

Cleanrooms by Industry:

Pharmaceutical & Medical Device

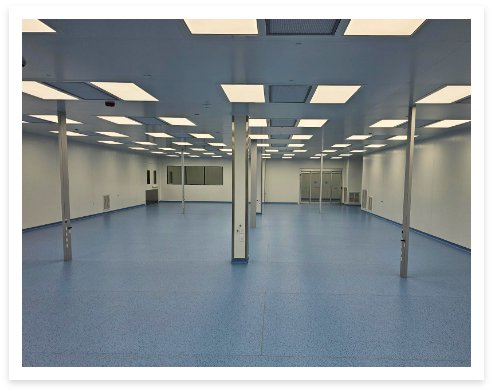

Pharma type cleanrooms require the highest level of cleanability. To achieve this, seamless wall and ceiling panel systems are preferred. They provide coving wall to wall and special joint compounds that make individual panel connections virtually disappear. These modular cleanroom solutions also provide the cleanest window and door combination because they are designed with and as part of the overall system. Unlike conventional construction, this cleanroom is a complete system designed with cleanability in mind – including its ability to withstand the myriad of disinfectants used in this industry.

Aerospace & Microelectronics

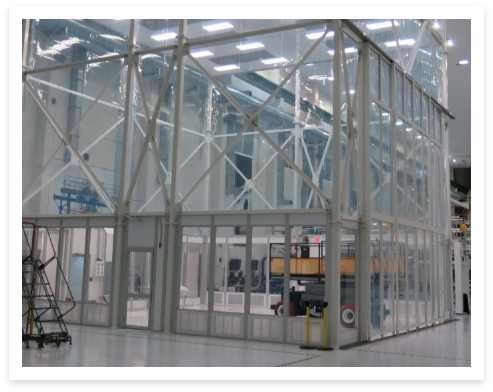

While cleanability is always important, some cleanroom environments don’t require as smooth of transitions between panels or doors. Cleanrooms for the aerospace and microelectronic industries are often more focused on strict particle counts or ESD concerns. These rooms often require more air exchange rates to achieve a higher cleanroom classification, which in turn requires more structural capacity. These types of modular cleanrooms can be load bearing, achieve much taller heights, and are available ina wide range of panel finishes depending upon your application.

Single Pass Cleanrooms

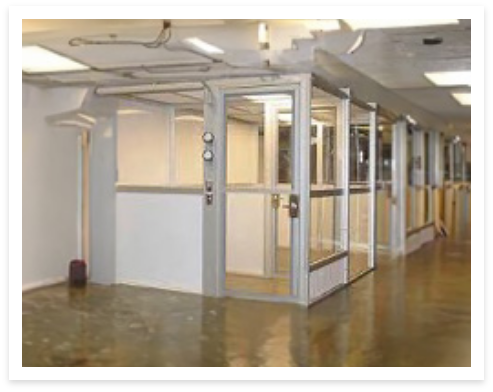

Single pass is a term that simply means the air entering the cleanroom does not recirculate. While there are certainly examples of hardwall cleanrooms, seamless, or otherwise may need a single pass air flow design for hazardous drugs – typically we refer to single pass cleanrooms to describe softwall cleanrooms and rooms similar in design. Softwall cleanrooms are typically constructed of a steel or aluminum framework with a self-supporting ceiling system to support HEPA fan filter modules. However, there are examples of single pass systems that offer hard and semi-hard wall panels that may provide real differential pressure if needed. Talk to one of our experts today to learn more!

Custom Applications

Ultrapure Technology has been in the cleanroom business for over 30 years! During that time, we have been asked to install some pretty unique cleanroom projects. From horizontal flow rooms to extremely tall projects, we have the experience to take on your next project.